Beer nerds turn dreams to reality 94 gallons at a time

September 21, 2016

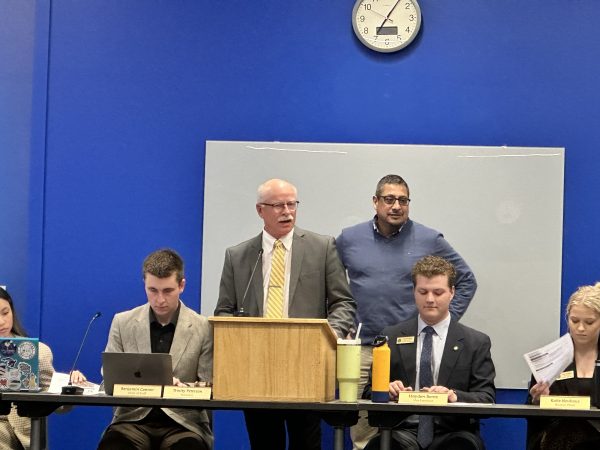

The Collegian sat down with Seth Koch of Wooden Legs Brewing Company to get insight into the beer brewing process and how Wooden Legs came to be.

For Koch, a self-proclaimed beer nerd, his love for beer started about 15 years ago.

“I had spent time at Colorado State and Illinois Institute of Technology in Chicago,” Koch said. “And at both places I kind of fell in love with really good craft beer, and then when I came to Brookings to finish school at SDSU in 2003, there was jack-diddly-crap. There was an obvious deficit of beers.”

That’s when Koch turned to brewing at home to recreate some of the brews he enjoyed. After spending some time in Europe, Koch paired up with his high school friend Steven Kreeger, and they later added on a third partner, Brant Mathiason.

It started out as brewing in a garage, but eventually they decided to make beers professionally. After three years of planning, Wooden Legs opened in 2013.

“We originally wanted to just do a brewery, but we didn’t think that would work in 2010, people just didn’t do it [in South Dakota],” Koch said. “So, we said we need to build an environment for people to be a beer nerd. We also wanted to keep some of the nostalgia from trips to Europe and to see Steve in the UK.”

Wooden Legs Brewing Company has since made hundreds of styles of beers using various international grains and ingredients, Koch said.

“The cool thing about all brewing is that it really hasn’t changed,” Koch said. “The process has pretty much stayed the same throughout history.”

The brewing process broken down

Wooden Legs Brewing Company tries to brew at least twice a week and is able to brew about 90 to 94 gallons of beer in one batch.

Step 1: Take the malted grain, grind it up, put it in the “mash tub” and add water from the hot tank.

“It looks like really poorly made porridge,” Koch said.

Koch said they use from 120 to 200 pounds of grains per batch depending on the style of beer. More grain leads to more fermentation and a higher intensity of alcohol. But color isn’t a good indicator of alcohol content.

“Just because it’s dark doesn’t mean it’s more or less alcohol,” Koch said.

Step 2: Let it sit for a specific time at a specific temperature at a specific pH (this varies

depending on what type of beer you want to make). The grain will then break down

and become water soluble.

Step 3: Extract the “liquid grain” (basically sugar water) from the mash tub and put it into the kettle to boil.

Step 4: Once the “vat” of sugar water is boiling, add in hops.

Koch said they add in anywhere from one to five pounds of hops. Hops adds bitterness, fragrance and is an antiseptic that helps preserve the beer.

Step 5: After the hops have been added, chill the contents.

Wooden Legs uses a plate and frame chiller, which Koch said is basically an inverted

radiator.

Step 6: Place the hops in a fermenter and add yeast. The yeast will consume the sugar,

produce carbon dioxide, produce flavor compounds and most importantly, yeast will

produce ethyl alcohol.

Step 7: Let the liquid sit in the fermenter for weeks or months (depending on the beer) and then transfer it to storage vessel.

“Our beer is never pasteurized, packaged or filtered,” Koch said.

Step 8 (Clean up): Part of this includes removing the grain husks and material that isn’t water soluble from the mash tub.

“We give this to a local farmer that feeds it to cattle because cows love it,” Koch said.

The love of beer is why Wooden Legs Brewery is set up to be a smaller brewery. This kind of set-up allows Koch and fellow brewers to “do whimsical stuff.”

The brewery has four to 13 craft brews on tap at any time. But Koch said the goal is to have around a dozen.

Wild Hare and Split Rock Creek Pale Ale are a couple of the most popular brews at Wooden Legs, though each customer has their own favorite. Koch said he doesn’t have a specific favorite himself.

“I love it all,” Koch said. “That’s the reason we do it.”