SDSU research could mean safer, greener military

January 18, 2011

Corey WackelNews Editor

Move over, Tony Stark.

SDSU is making a move in military research to be conducted by the university’s electrical and mechanical engineering departments.

The project is being done as part of a proposal to help produce technology that can be used by U.S. military.

The proposal came from congressional earmarks recommended by Sen. Tim Johnson and former Rep. Stephanie Herseth Sandlin.

Electrical Engineering

The electrical engineering side of the research is focused on alternative power technology.

Dennis Helder, associate dean for research at SDSU, said researchers are trying to help the military reduce its usage of petroleum.

The plan to reduce dependence on petroleum was outlined in a 5-year proposal, which was made up of contracts from the military.

“One of the largest liabilities in Afghanistan comes about because of the fact that diesel fuel trucks become a major target within traveling convoys,” Helder said. “If one fuel convoy is taken out, multiple units could suffer from that.”

In trying to reduce the usage of fuel through generators, several different ideas have led to promising results.

The use of microgrid systems is one possible solution. These systems use energy storage and alternative energy generation to reduce the amount of fuel used by standard military generators.

Solar cells, which have been made portable and are able to produce energy quickly, is also an idea being tested. In a related experiment a substance was painted onto test equipment with a stripped-down surface, resulting in a solar cell that was capable of producing electricity.

About 20 people are involved in the research, including faculty, engineering staff, and both undergraduate and graduate students.

“The fact that students can work on the research is really exciting,” Helder said.

Seth McGill, an electrical engineering graduate student, was hired to do research. He completed his undergraduate degree in May 2010.

“I became involved with research within the first semester after graduating,” McGill said. “I’ve been working on research projects for about a year now and I think it is a unique opportunity to get away from computers for a while and to just get some hands on work.”

For McGill, being able to observe the entire process is possibly the biggest reward.

“I really want to see an end product,” McGill said, “and being able to go from an idea, to designing and seeing that idea producing something that works, is a great reward.”

In their endeavors, the SDSU research team is partnered with Radiance Technologies, an Alabama-based company serving as a subcontractor. Radiance Technologies works on the design and development of the technology produced through the research done at SDSU.

“The company takes the basic concept so that the military can adapt ideas to implement the technology,” Helder said.

Helder believes that advances in technology help U.S. troops across the world.

“I would say that my major goal in doing this research is to produce technology that can … save as many lives as possible,” he said.

Mechanical Engineering

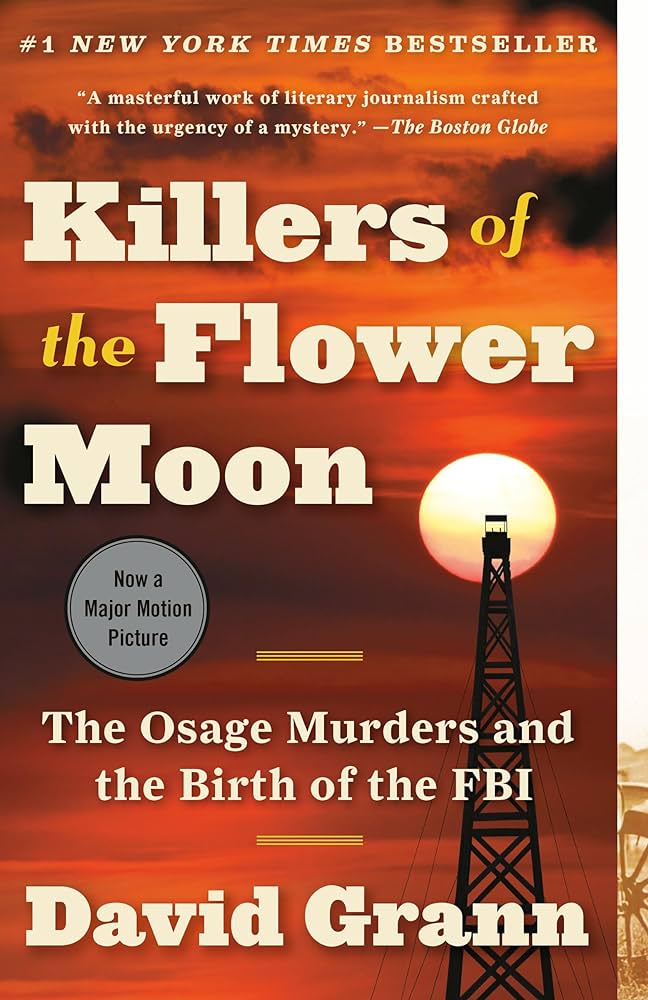

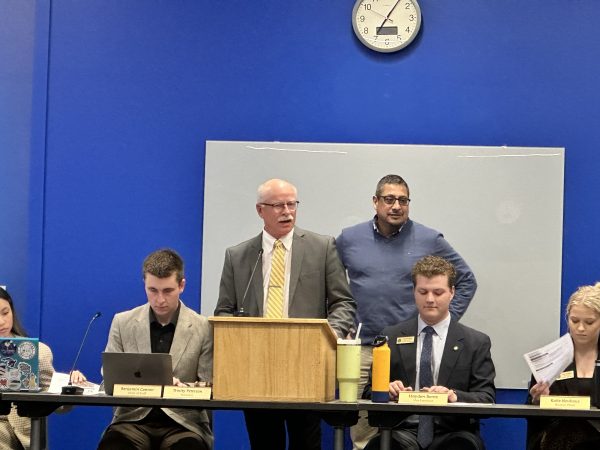

In the mechanical engineering department, research is largely dedicated to materials testing.

“When we were originally given the money to conduct research, the proposal had three main goals outlined,” said Fereidoon Delfanian, the director of the materials evaluation and testing laboratory (METLAB). “Those three goals were to provide service to the Department of Defense, to provide service to South Dakota industries and the region around us, and to create a setting to serve research and education purposes.”

As with the electrical engineering department, research is ongoing and continues to produce results.

In 2008, $2.6 million allotted by the Department of Defense went toward the development of what the department called a fatigue-odometer sensor (FOS) and another $1.84 million went toward funding nondestructive testing of lightweight cannon systems.

Both projects were aimed toward determining the point at which military vehicles and weapons begin to wear down and become unsafe, Delfanian said. Research is also being done to determine the life of a cannon barrel, catching potential problems before they arise.

SDSU went from a subcontractor to a prime contractor in 2009 and began working with U.S. Army Benet Laboratories in New York, a primary design, development, and engineering facility for a wide range of military equipment. As a prime contractor, SDSU began to take more responsibility for research.

The Future

Significant research continues in both departments, and a new $9.3 million contract was given to SDSU for continued testing of gun barrels used by the military. That contract will run through 2013.

Faculty at SDSU are in constant contact with what the military calls a contract officer’s technical representative.

“Their job is to monitor the progress made,” Helder said. “I have contact with him once a week, and we have a quarterly site visit.”

#1.1898197:3689467306.png:metlab-BRUA.png:The METLAB has a variety of machines to test the hardness and density of different materials for the U.S. Army.:Collegian Photo by Stephen Brua