Students ‘upscale’ career potential in Quarter Scale Tractor Club

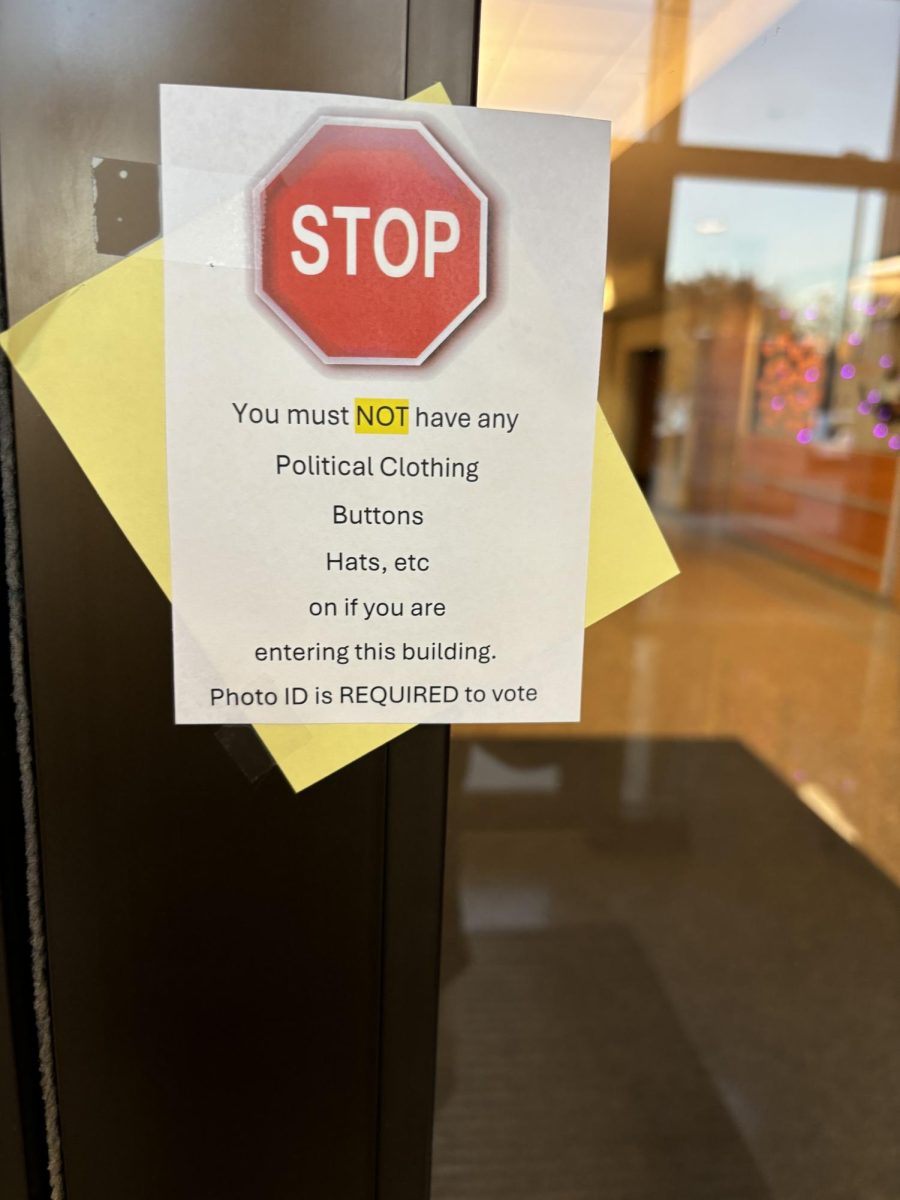

Logan Turgasen works on a quarter scale tractor to prepare for the international competition.

February 28, 2023

Students in South Dakota State University’s champion-level quarter-scale tractor club are not only internationally competitive with their machines, but excel above their peers with real-world industry experience.

“I wanted to build things while I was here at college, and the quarter-scale tractor club was the perfect opportunity to also hang out with other ag kids,” Phillip Black, the quarter scale tractor club president and junior ag systems tech major, said. “We’re very hands-on and get things done.”

The nearly 20 members of the quarter-scale tractor team are responsible for complete design, fabrication and production of a tractor the quarter of the size of an industry standard tractor during the school year. The competition to test their work alongside schools from around the world takes place June 1-5 in Peoria, Illinois. For SDSU team members, this contest is a multi-year tradition, and they have two international wins. In 2018 and 2022, SDSU had the overall champion tractor and took home both a permanent and traveling trophy.

Douglas Prairie, the club’s adviser and lecturer in the ag and biosystems engineering department, said faculty primarily act as a support system for the students to help acquire materials and interest new members.

“The direction of the design of the tractor is by the club members, it’s not like an academic exercise – it’s more like a hobby that you can put on your resume,” Prairie said about why students should join the club. “It can take a fair amount of time but has become a fraternal type organization within our department.”

At the start of the year, all ‘A’ teams are supplied with the same engine and two back tires to start the playing field even. After that, the students must finish all aspects of creating the best machine. There’s also an ‘X’ team that brings back its tractor from the previous competition year with any modifications they made to make it better.

Before the contest begins, contestants must have their tractor approved by a tech inspection which measures all the safety features of the machine. If the tractor is denied, the students must fix whatever safety shortage that was identified and bring it back for re-evaluation before continuing in the contest.

The pulling portion of the contest is worth the most points. Not only does the tractor need to weigh less than 900 pounds on contest day, but one of its challenges is to pull 1,100 and 1,600 pound sleds in a race for the most distance pulled.

The next highest score in the contest is assigned to a 25-page written report and presentation. Students must write about the ideas they generated and include designs and pictures of the entire process. The idea behind the presentation is for team members to “sell” their tractor to a panel of potential buyers made up of industry leaders.

Other factors of the tractors’ success are measured in their durability and maneuverability. These competitions include a track designed with lots of speed bumps that the tractor must race as many laps around as possible, and another course with poles for the driver to either avoid or specifically knock over.

All aspects of the International Quarter-Scale Tractor competition are representations of real industry needs in farming equipment and is hosted by the American Society of Ag and Biosystems Engineers.

Many students recognize the value of participating and learning these skills while in college and those individuals stand out to companies looking to hire.

“The point [of the contest] is to get relevant industry experience,” Sam Meyer, a sophomore agriculture and biosystems engineer major, said. “We’re literally doing what we’d be doing at our future jobs.”

Students have the opportunity to see their designs, whether good or bad, be brought to life in a real working machine, with equipment and parts supplied by their department and a variety of sponsors.

“The coolest part is we’re not only designing it but building it from the ground up,” Meyer said. “[By writing the paper] you have to justify your designs and explain why someone should buy it.”

Wisconsin native and SDSU student Logan Turgasen personally testifies to the importance of the quarter scale tractor club experience after his first internship at Sage Ag, which set him up for a summer position with John Deere in Moline, Illinois.

“When you tell employers you were on the quarter scale tractor team, it usually gets a reaction,” Turgasen, an ag and biosystems engineering major, said while talking about his experience with industry professionals.

This year, the members are excited to use a 3D printing machine for the first time to improve fabrication of several parts and test their ideas before using the actual material.

The team will again be competing in the international competition in June with high hopes for their new designs to continue the champion tradition.