Departments collab to improve classroom accuracy

Mechanical engineering students develop device for nursing labs

SDSU Marketing and Communications

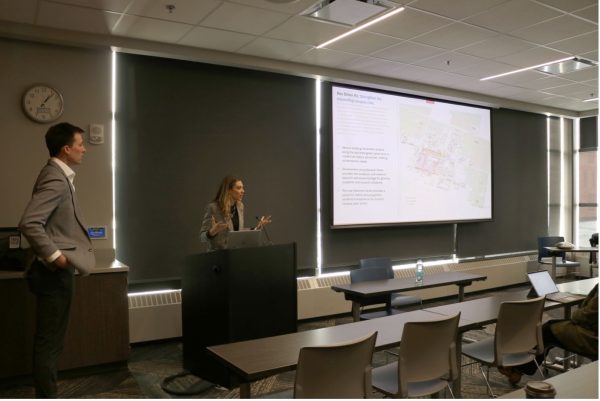

Mechanical engineering majors Maddie Mingo (from left), James Smith and Eric Beehler place controls onto a defibrillator board in a College of Nursing simulation lab.

February 1, 2022

In South Dakota State University nursing labs, students practice realistic simulations of scenarios they will likely face on the job. But there was one problem: there wasn’t an easy way to accurately simulate defibrillation. Now, thanks to mechanical engineering students, defibrillation labs are about to get shockingly more realistic.

Alyssa Zweifel, a College of Nursing assistant professor and healthcare simulation center director, and Michael Twedt, a program engineer in the Department of Mechanical Engineering, have worked closely with fall 2021 students Eric Beehler, James Smith and Maddie Mingo to design and construct a new device that simulates a patient’s “jolting” during defibrillation.

The engineering students developed an “always-there backboard” for simulations that require use of a defibrillator. The backboard sits underneath the mannequin “patient” and can produce realistic upward force when students use the defibrillators—just like a real person would. The function is activated via remote control and powered by battery, which eliminates unnecessary wires and increases mobility of the device.

The group of students started the design process in spring 2021.

“We needed to understand what technologies currently existed that produce a similar effect. We also needed to understand the simulation environment and the design constraints,” Mingo said. By the start of the fall 2021 semester, the team had a design in mind and was starting the prototype phase.

But the project wasn’t without ups and downs.

“The internal mechanism of the prototype includes lever arms that attach to four servo motors,” Mingo said. “Initially, we printed these parts in PLA (polylactic acid) using a 3D printer… Unfortunately, the material proved too brittle for our application, so we had to switch to aluminum parts.”

The team then spent about 40 hours in the shop to machine the aluminum parts by hand.

The electrical components also went through multiple redesigns. The team experimented with 7.4V Lithium-ion batteries, similar to what is used in remote-controlled cars, but not enough power was provided. The team’s next step was an 18V Lithium-ion drill battery, which required a slight design change.

“The design, test and redesign process continued until finals week this past December. We tested the prototype that we had with the SDSU Nursing Department on Dec. 16th, 2021,” Mingo said.

Smith, Beehler and Mingo’s project was a part of the ME 478 and ME 479 classes mechanical engineering students take during their senior year. Students typically spend between 70 and 120 hours each semester on the project, according to Twedt.

“Anyone can submit a project. It often is a manufacturing company or a new product design, but it can be anyone that requires some engineering help, including SDSU departments, researchers, labs or groups,” Twedt said.

Zweifel acts as a bridge between the College of Nursing and the Department of Engineering. She met with the team monthly to discuss developments in the project.

For Zweifel, being able to communicate the needs of the nursing department while understanding the mechanical engineering side has been a learning curve, but one she feels she is getting better at.

“They’re really good at dumbing it down for me,” Zweifel joked. “They tell me where they’re at, and I ask if they have any nursing questions.”

The College of Nursing has partnered with mechanical engineering students previously, including during the fall 2020 semester when engineering students Abbdullah Alrashidi, Zachary Dorn, Denner Dougherty and Ashley Jorgensen produced artificial bone material for use in intraosseous injection nursing labs.