Boiler upgrades will increase energy conservation

January 25, 2011

Briana DorrenNews Editor

Energy conservation is becoming increasingly more important, and SDSU plans to keep up with the changes, as funds are being put to use renovating the facility’s equipment.

Last month, the South Dakota Board of Regents approved plans to move towards being a greener campus here at SDSU. “SDSU’s Preliminary Facility Statement and Facility Program Plan for the Central Heating Plant Boiler Replacement and Plan Upgrades” is the project title for the plans, which, in lesser terms, include replacements and renovations of equipment in the Central Heating Plant in order to heat the many buildings on campus with greater efficiency.

According to the SDSU website, the Central Heating Plant heats over 2,788,876 square feet of campus buildings. Coal, gas, and oil burning boilers provide steam via underground tunnels to heat buildings across campus. Boilers also provide heat for cooking, cleaning, and domestic water heating, among other uses.

Energy Conservation

Winter days see a constant billow of steam pouring from the plant, a result of the boilers hard at work. In order to make this constant running of the boilers more efficient, a group of individuals saw the need to implement energy conservation measures. These individuals include Barry Mielke, Roger Thue, Dean Kattelmann, and others whose work involves them with the heating plant. After meetings with the BOR and also with the Office of State Engineers, plans to begin the conservation project were settled.

One down, 11 months to go

Already over a week into the project, completion is set for Dec. 2011. Currently, work is being done on one boiler, with the rest to follow. “There is a lot of heating to maintain, so we are taking one boiler down at a time so that there are always some running,” said Barry Mielke, project manager and senior mechanical engineer at the heating plant. According to Mielke, renovations involve recovering the heat from boiled water and adding it to the boiler feed water, a process which helps reuse that energy.

Also being replaced are pneumatic controls with digital controls. “This will give us tighter control and improve emissions,” Roger Thue, an engineer and supervisor of Utility Division Management, said. “We’ve had a need for boiler controls for some time,” said Thue.

Stack economizers are also being added. These will take the heat out of exhaust to be used to preheat water, another energy conservation measure.

Economic Recovery

Funding from Obama’s federal stimulus bill is instrumental in this project, namely the American Resource and Recovery Act. The stimulus bill is focused on economic recovery and as such, SDSU was granted funding to cover all but a small portion of the estimated $5,787,000 needed to create a more energy efficient heating plant.

Work is in full swing at the Central Heating Plant; while renovations will not be complete until Dec., according to Thue the funds from the stimulus bill must be spent by Mar. 2011.

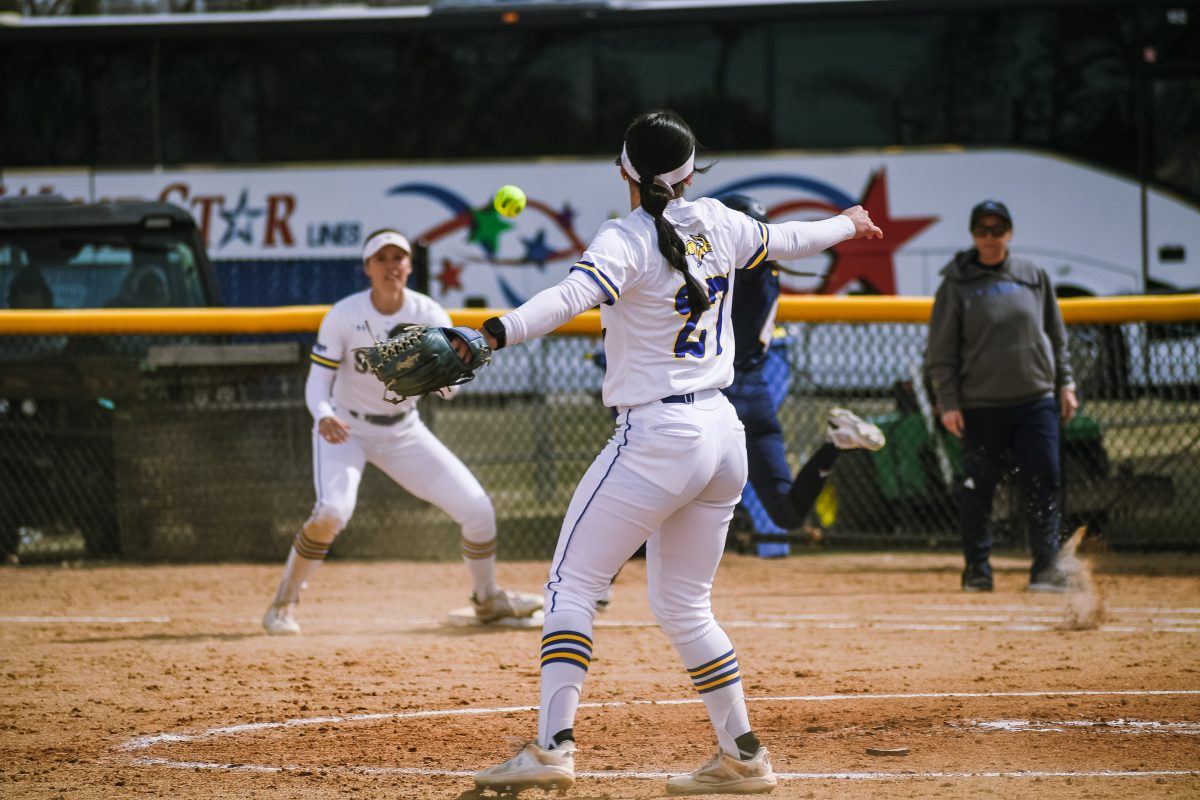

#1.1918797:2322146730.png:coalplant-GALLAGHER.png:Steam, often mistaken for smoke, pours from the Central Heating Plant. Boilers run 24 hours a day, heating SDSU?s campus. :Collegian Photo by Robby Gallagher